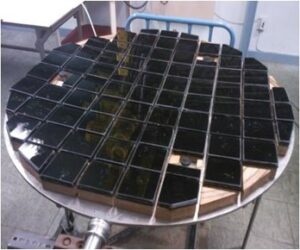

The POLARIS facility has a total of 6 polishing machines and several glass-machining tools.

Polishing machines:

- double motorized polishing machine for diameters up to 450mm

- 2 manual polishing machines for diameters up to 450mm

- 1 polishing machine dedicated to the manufacturing of VCM (variable curvature mirrors) for the delay lines of the VLTI mode of the ESO VLT

- 1 polishing machine for diameters up to 1200mm

- 1 polishing machine for diameters up to 1000mm.

Glass-machining tools:

- edging and spherical generator machine

- saw with diamond circular disc for glass cutting

- glass-drilling machine

To measure radii of curvature, surface form error, roughness and aspect-cosmetics of optical surfaces, the facility uses in routine state-of-art equipments.

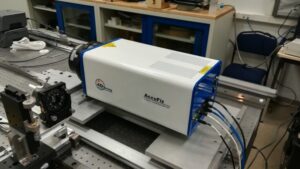

- surface form error measurement: 3 Fizeau phase-shifting interferometers with 100mm diameters and reference spheres (plane, f/1.5, f/3, f/10, f/23); 4D Technologies Accufiz (mounted on an optical ruler), Intellium Z100 (mounted on an optical ruler), ESDI H2000 (with simultaneous phase-shifting and integrated attenuator)

- radii of curvature measurement: spherometers and radii-of-curvature benches

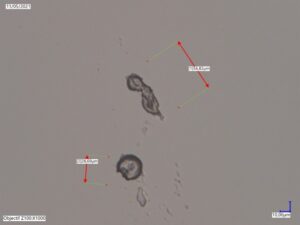

- aspect/cosmetics: digital microscope Keyence VHX-7000 with objective x2000, binoculars, scratch-dig standards

- roughness: white-light interferential microscope WYKO NT-9100.